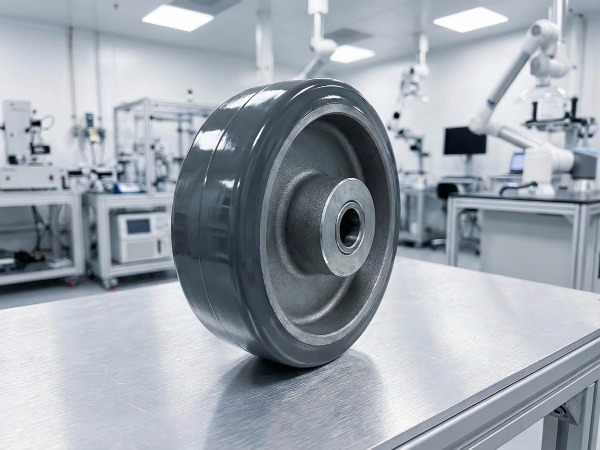

“Polyurethane wheel in Bangalore feature high-performance Shore A 95 PU wheels for satellite transfer, achieving a 300% load increase, zero clean-room contamination, and 40% cost savings.”

1. Project Background

Client: A leading private aerospace technology firm located in the Bangalore Industrial Zone, India.

Application: Transportation of satellite structural components and precision electronic assemblies between Clean Rooms and integration workshops.

Core Challenge: The previously used imported rubber wheels suffered from severe "creep" (vibration caused by material deformation) when carrying 2.000 kg precision payloads. Additionally, friction left black carbon marks on the clean room's epoxy floors, and frequent replacements led to costly production downtime.

2. Technical Challenges

High Cleanliness Standards: Must use non-marking, non-volatile materials to ensure zero contamination of aerospace components.

Extreme Static Loads: Satellite transfer trolleys may remain stationary for extended periods; wheels must not develop permanent "flat spots."

Indian Supply Chain Localization: The client aimed to implement "Make in India" processing to shorten lead times and reduce maintenance costs by 40%.

3. Polyurethane Coating Process

To meet aerospace-grade requirements, the localized technical process in India followed these rigorous steps:

Step 1: Precision Hub Inspection High-strength aerospace-grade aluminum alloy (7075-T6) was used for the wheel hubs. Before coating, ultrasonic testing was performed to detect any casting defects, ensuring structural integrity under high pressure.

Step 2: Chemical Adhesion Bonding This is the most critical phase. Due to India’s humid climate, the facility utilized specialized chemical grit-blasting followed by the application of imported Chemlok adhesives. This ensures a peel strength between the polyurethane and the metal hub of over 20 N/mm

Step 3: Vacuum Casting Process High-performance polyurethane prepolymer (selected hardness: Shore A 95) was used. Casting was performed in a controlled environment in Bangalore using vacuum degassing to eliminate internal air bubbles, preventing internal cracking under heavy loads.

Step 4: Precision Machining After curing, CNC lathes were used for finish-turning the outer diameter. Run-out tolerances were kept within $0.05,text{mm}$ to ensure absolute smoothness during the transport of sensitive equipment.

4. Results Comparison

Indicator | Before (Standard Rubber Wheels) | After (Local Polyurethane Coating) |

Load Capacity | Prone to deformation; limited capacity. | 300% increase; no detectable deformation. |

Floor Protection | Left black streaks; damaged epoxy floors. | Non-marking; protects floor integrity. |

Operational Vibration | High vibration; risk to payloads. | Smooth operation; protects sensitive sensors. |

Maintenance Cost | Replaced every 6 months. | Expected service life of 3+ years. |

5. Conclusion

By transitioning from an import-dependent replacement model to localized precision polyurethane coating in India, the aerospace firm not only bypassed heavy import duties on spare parts but also significantly enhanced the safety of the satellite assembly process. This case demonstrates the critical value of polyurethane bonding technology in localizing the Indian aerospace supply chain. Contact us for your equipment!