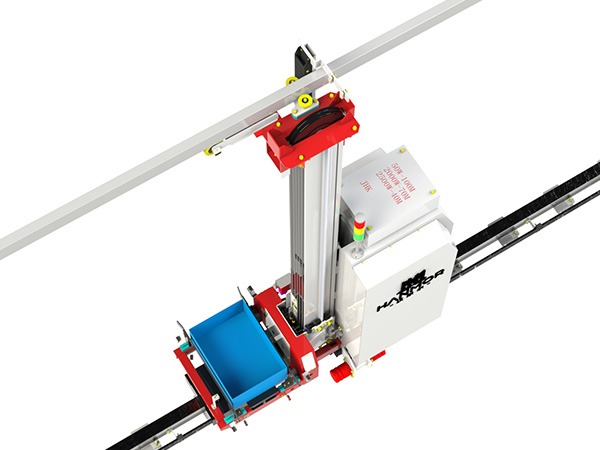

In Automated Storage and Retrieval Systems (AS/RS), the speed of the stacker crane often determines the throughput efficiency of the entire warehouse. However, as these cranes traverse masts dozens of meters high at high speeds, how do they maintain vertical stability and suppress high-frequency vibrations? The answer lies in the Polyurethane Guide Wheels that run tightly against the rails.

Core Positioning and Precision Layout

Guide wheels are typically installed in pairs at the top and bottom of the stacker crane mast. By maintaining tight contact with the lateral rails (both top and ground rails), they form a stable geometric constraint system. If the drive wheels are the "legs" of the stacker crane, the guide wheels are the "stabilizers" that ensure it stays on course without swaying.

Why Polyurethane is the Premier Choice for Guide Wheels

Compared to traditional metal or engineering plastic wheels, high-performance polyurethane (PU) offers irreplaceable advantages in guiding systems:

1. Exceptional Rotational Precision and Smoothness

Guide wheels require extremely tight concentricity tolerances. Our polyurethane guide wheels undergo precision grinding to ensure minimal run-out during high-speed rotation. This directly reduces horizontal mast sway, allowing the top of the crane to remain stable within millimeter-level tolerances even at peak speeds.

2. Efficient Vibration Absorption and Structural Protection

Stacker cranes generate significant lateral impact forces during rapid starts and stops. Polyurethane possesses natural damping properties, acting like a "shock absorber" to dissipate micro-vibrations and impact energy between the mast and the rail. This not only lowers operational noise but, more importantly, protects expensive steel structures and rails from high-frequency fatigue damage.

3. "Zero-Wear" Rail Protection

Metal-on-metal friction leads to rapid rail wear and the accumulation of debris. Polyurethane is "tough yet flexible"—it provides sufficient structural support without scratching the rail’s surface coatings or base metal. This significantly extends the maintenance cycle of the entire rail system.

4. Low Deformation Under High Loads

For stacker cranes with ultra-high masts, we utilize high-modulus polyurethane formulations (e.g., 93A-95A Shore hardness). This material maintains its shape under high pressure, ensuring consistent guiding gaps and preventing positioning deviations caused by wheel deformation.

Summary of Benefits

By upgrading to precision-customized polyurethane guide wheels, businesses achieve:

Increased Speed: More stable operation allows equipment to reach higher travel speeds.

Quiet Environment: Effectively eliminates metal clanging, creating a more ergonomic workplace.

Cost Efficiency: Reduces rail maintenance costs and lowers the failure rate of electronic components caused by vibration.

[Inquire Now] Improve your stacker crane’s operational precision, starting with high-performance guide wheels.